Written by: Graeme Marsh (Z BioScience Inc.)

After cleaning, BioPure is introduced to prevent biofilm reformation, benefiting flock health and growth. Data analysis reveals lower mortality rates with BioPure, compared to traditional additives, impacting key metrics like feed intake, weight gain, gut development, livability, and overall weight. The consistent use of the BioClean and BioPure combination emerges as a successful strategy for improving livestock performance, contributing to enhanced financial outcomes for producers.

KEY TAKEAWAYS:

- Recurrence of biofilm in the water lines decreases the likelihood of health challenges for livestock relying on these water sources.

- Enhances the overall well-being and establishes a proactive resilience that positively influences measures of Livability and Weight.

Water makes up between 70% and 75% of the body mass of broilers and turkeys and is one of the three essentials for Life, along with Food and Air. The quality of the water and the infrastructure used to deliver the water to poultry livestock, therefore, is critically important to the vitality and well-being of flocks throughout the grow-out process. What follows here are numerous data sets that demonstrate that the use of BioPure Probiotic Water Additive in poultry waterlines is a proven means of improving flock performance when the waterline system has been properly prepared by cleaning it out with BioClean Probiotic Biosurfactant Cleaner.

This discussion will be in three parts:

- Cleaning waterlines with BioClean

- Impact of adding BioPure to the water supply

- Where BioClean and BioPure fit it (or not) with conventional practices

Cleaning Waterlines with BioClean

Biofilm that harbors and generates unwanted pathogens in waterlines that can negatively impact a flock’s growth and livability rates represents one of the most significant unseen challenges for producers. Conventionally, chemical additives such as Chlorine Dioxide (ClO2) have been added to waterlines to inhibit the build-up of such biofilms, but do they work?

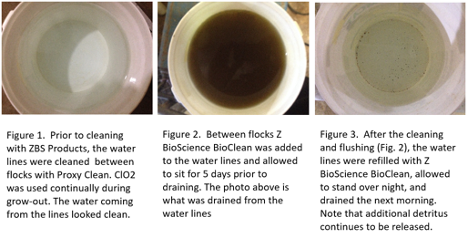

Consider this example:

NOTE: BioClean does not need to be left in waterlines for 5 days. 24 to 48 hours is sufficient residency to trigger the release.

It is well known that chemical disinfectant and sanitizing products (such as chlorine and chlorine dioxide) do not dismantle biofilm, which is confirmed in this example. So why does BioClean work at releasing the biofilm from waterlines?

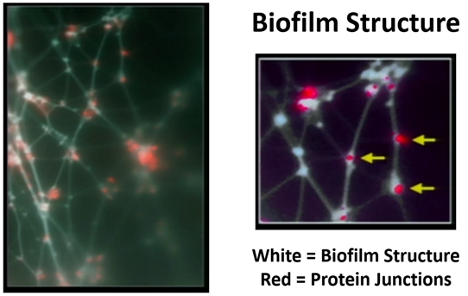

Biofilm is made up of two core components:

- Protein Junctions

- Strands of Polysaccharides

The Protein Junctions hold the Polysaccharide Strands together, much like cement holds bricks together in a brick wall. The probiotics in BioClean (and BioPure) are living entities and need food to survive. The Protein Junctions that hold the biofilm structure together represent an available food source for the Probiotics.

When the Probiotics consume these Protein Junctions, it’s like removing the cement in a brick wall. Once the cement is removed, there is nothing holding them or the wall together, so the wall becomes structurally unstable and collapses.

That is what happened here in this waterline example. The Probiotics in BioClean consumed the Protein Junctions in the unseen Biofilm, triggering the collapse in its structure and subsequent release. So, cleaning out the waterlines with BioClean will deliver superior results and healthier water.

Adding BioPure to the Ongoing Water Supply:

Once the waterlines are clean, preventing Biofilm reforming is critical. Adding BioPure Probiotic Waterline Additive to the water is the solution not just to inhibiting biofilm reformation but also provides demonstratable, proven benefits to flock health, livability, and growth.

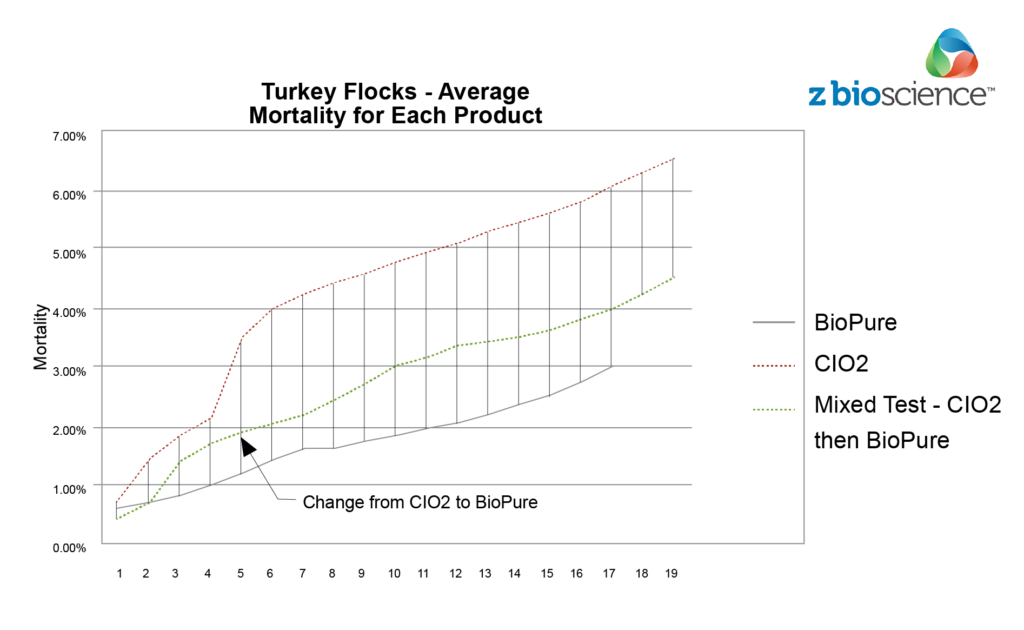

Data Set #1 – BioPure vs ClO2 – Average Flock Mortality (Turkeys):

The data used for the chart below came from three commercial turkey barns on the same ranch of the same size and bird population. The water source was also the same.

This chart highlights how when BioPure was added to the waterlines instead of ClO2, the mortality rate dropped to:

- only 3% mortality with BioPure vs

- over 6% for the flock using only ClO2.

After viewing the significantly lower mortality rate within the first 5 weeks of using BioPure instead of ClO2, this producer decided to switch a 3rd barn from ClO2 to BioPure at week 5. Even though BioPure was not used for the first 5 weeks by switching away from ClO2 to BioPure, the flock in that third barn also saw a significantly lower mortality rate of 4.5% vs 6.5% for the barn using only ClO2. It is also important to note that that the flock using only BioPure achieved harvestable weight earlier!

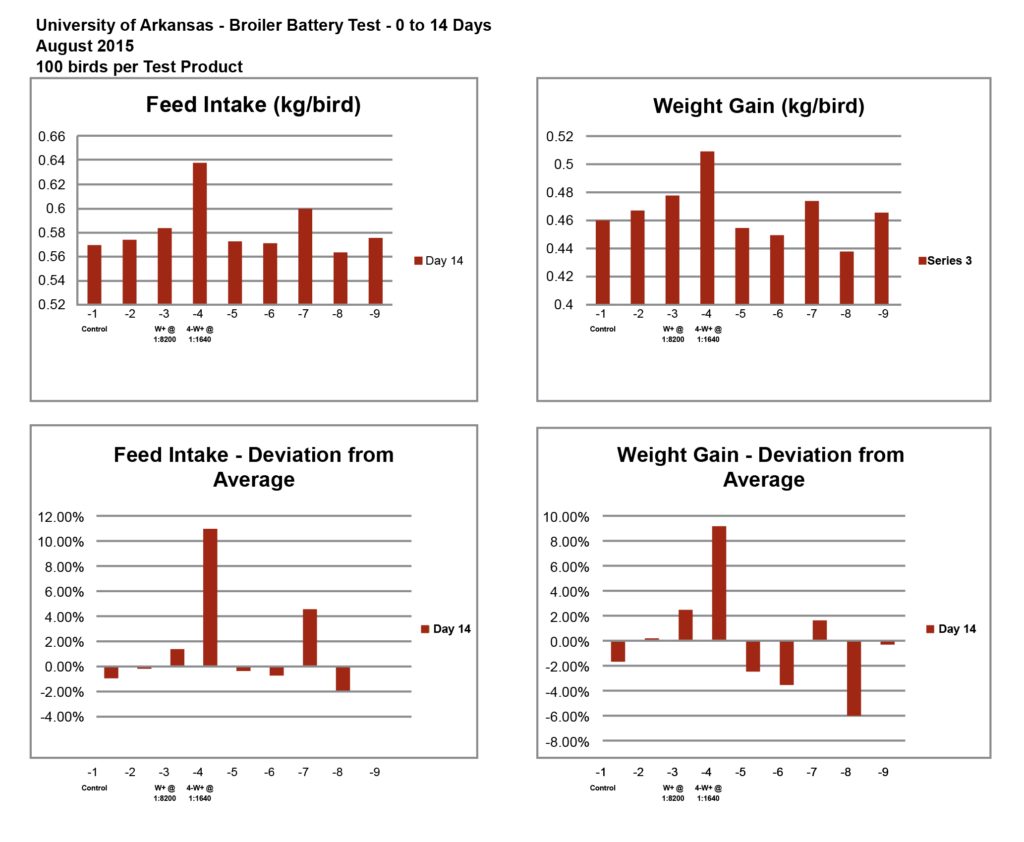

Data Set #2 – Impact of BioPure vs ClO2 and other water additives (Broilers)

The following data sets came from trials conducted by the University of Arkansas to compare the impact on key metrics by BioPure compared to other common chemical water additives used to maximize bird health and growth, such as ClO2.

BioPure was applied at two different dilution rates:

- 1:8200 (normal recommended rate) – #3 in all the Uni of Arkansas data

- 1:1640 (super ratio – used in past on flocks with health issues) – #4 in all the Uni of Arkansas data

Data on the products Z BioScience’s BioPure was being compared with were not provided by the University. The Control flock had nothing added to the water.

Feed Intake and Weight Gain Data:

- BioPure at 1:1640 dilution generated:

- by far the best Feed Intake and Weight Gain

- BioPure at 1:8200 dilution generated:

- The 3rd best Feed Intake performance and the 2nd best Weight Gain

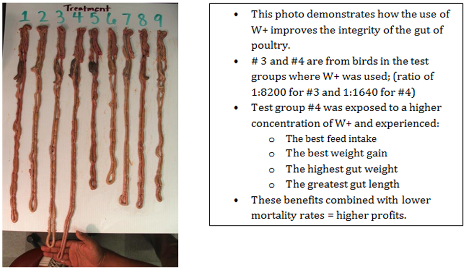

Gut Length

Gut integrity and length are critical determinants of both the general health of a bird and its performance.

As this picture clearly shows, using BioPure at both dilutions generated substantially better bird gut development, explaining why BioPure produced superior Weight Gain performance.

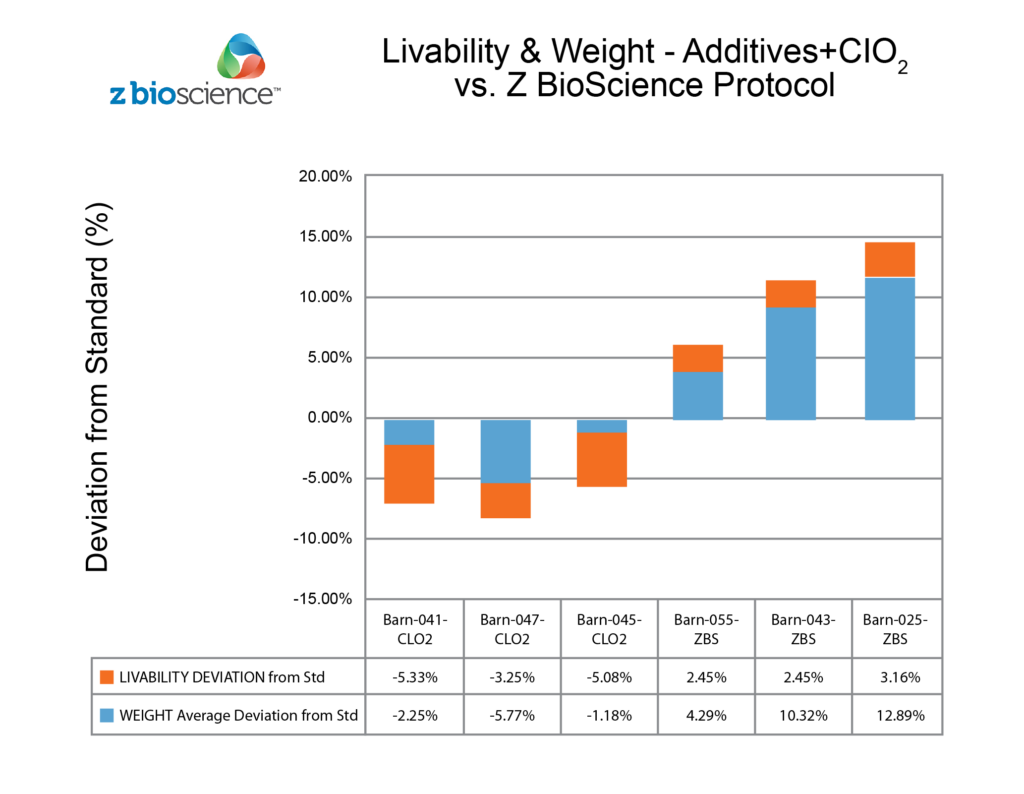

Data Set #3 – BioPure vs ClO2 (Turkeys – actual commercial barn data)

A large commercial organic turkey producer compared the performance of BioPure used in 3 different barns to ClO2 being used in 3 other barns.

The key performance metrics measured were:

- Livability

- Weight

In all instances, the barns using BioPure delivered better Livability and Weight performance.

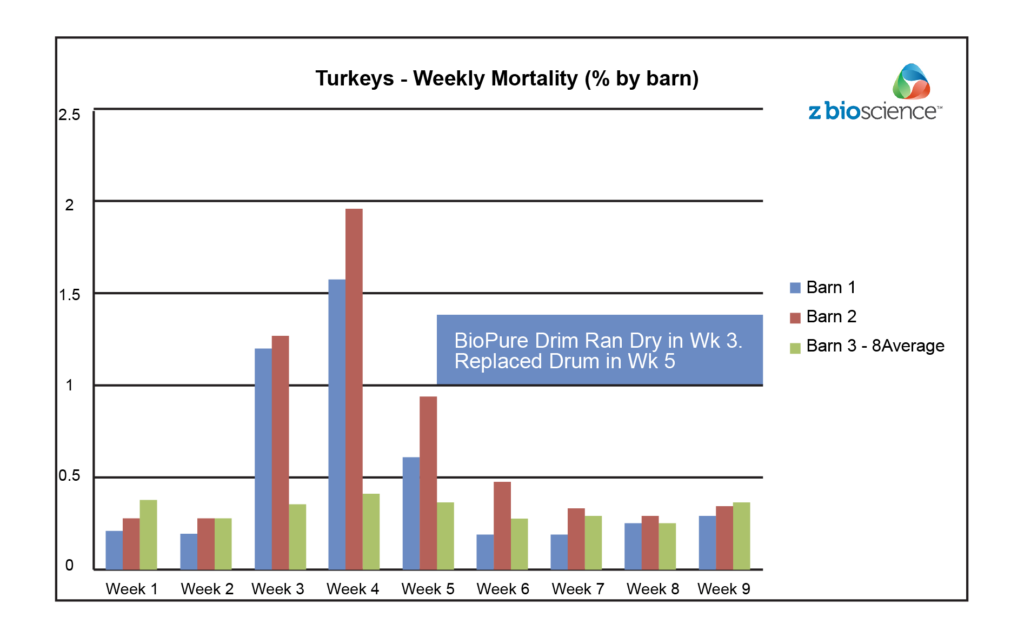

Data Set #4 – Impact on flocks when BioPure is not used

In this data set the water systems servicing multiple Turkey grow-out barns ran out of BioPure. For the 3 weeks BioPure was not added to the water (weeks 3, 4 & 5 of the grow-out), mortality rates surged by between double and quadruple the levels of when BioPure was available to the birds.

Conclusions:

The outcomes highlighted in Data Set #4 are incredibly important!

Key to any livestock program is building resilience within the animal as a primary means of ensuring maximum performance and the ability to overcome unexpected and unwanted assaults on the health of the animal. Cleaning the water lines with BioClean to remove unwanted pathogens that compromise an animal’s performance is a critical 1st step.

Ongoing use of BioPure delivers two critical components:

- It inhibits biofilm reformation in the lines and, in doing so, reduces the risk of potential health assaults on livestock dependent upon those water lines.

- The probiotics in BioPure find their way into the guts of livestock, which strengthens their overall health and builds a level of preventative resilience that improves Livability and Weight metrics.

The outcomes displayed in Data Set #4 highlight how BioPure significantly contributes to the resilience of flocks to assaults that increase mortality. Data Sets #2 and #3 highlight how BioPure beneficially impacts weight gain. This makes sense, given the significant additional length in the guts of birds using BioPure in the photo. Combining cleaning waterlines with BioClean and then adding BioPure has consistently contributed to improvements in critical livestock performance metrics that improve the financial outcomes for producers.